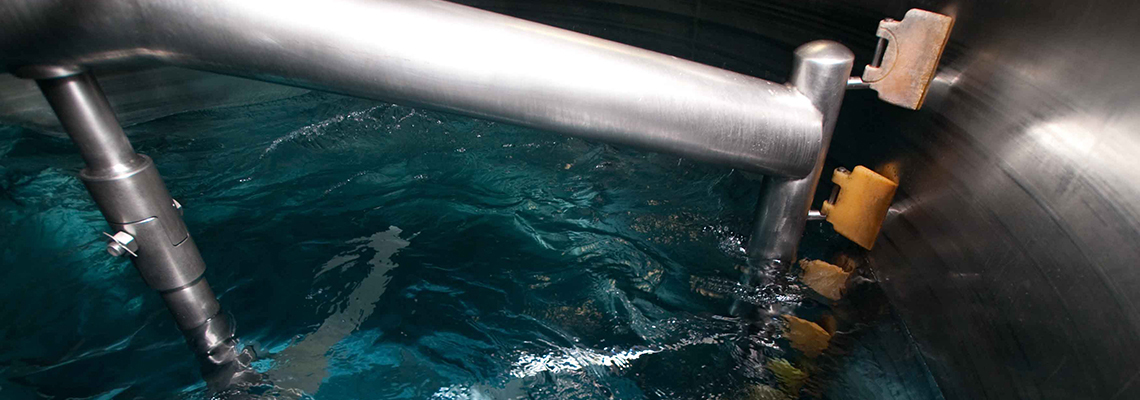

At ChemRite CoPac, our mixing vessels were custom engineered to accommodate distinct variations in liquid, lotion, crème and paste blends. They are able to accommodate the simplest mixture to the most complex suspension. Each mixing vessel has been tailored to fit ChemRite’s exacting quality standards and the need for maximum flexibility. Our experienced team will be pleased to recommend a mixing vessel which best fits your product.

Mixing Vessel Features*

- Environmentally Controlled Mix Rooms

- Custom Designed 316 Stainless Steel Tanks

- Fiberglass Tanks

- Polyethylene Tanks

- Stainless Steel Portable Tanks for Scale Up and/or Pilot Production

- Weight/Weight Batching Systems

- High Sheer Blending Mills

- Eductors

- Homogenizers

- Center turbine type full length adjustable speed and direction blending

- Full length side sweep, variable speed and direction blending

- Full jacketed for pressure steam and closed-loop chilling

- Integrated temperature control system

- Integrated ports for add-on customizing of each tank (mills, homo-eductors, etc)

- Load cell weighing system at 1 lb. increments to 40,000 lb. for bulk additions

- In-tank integrated variable speed homogenizer capabilities

- Top/bottom port recirculation

- Tanks: 200 to 5,000 gallon capacity

*For more information on ChemRite’s blending capabilities, please visit our Blending webpage.